Dust Collection System Design Software

Dust collection system design software. AST Engineering experts will visit your plant and review your application in details. Some tools provide adequate dust collection ports while others most dont and you will need to devise your own enhancements. We will in next six weeks talk about manual systems semi-automated systems and fully automated systems.

Planning Your Dust Collection System Planning your duct layout on paper is the first step. Read reviews on the premier Web Design Software in the industry. Dust Collection Design Guide.

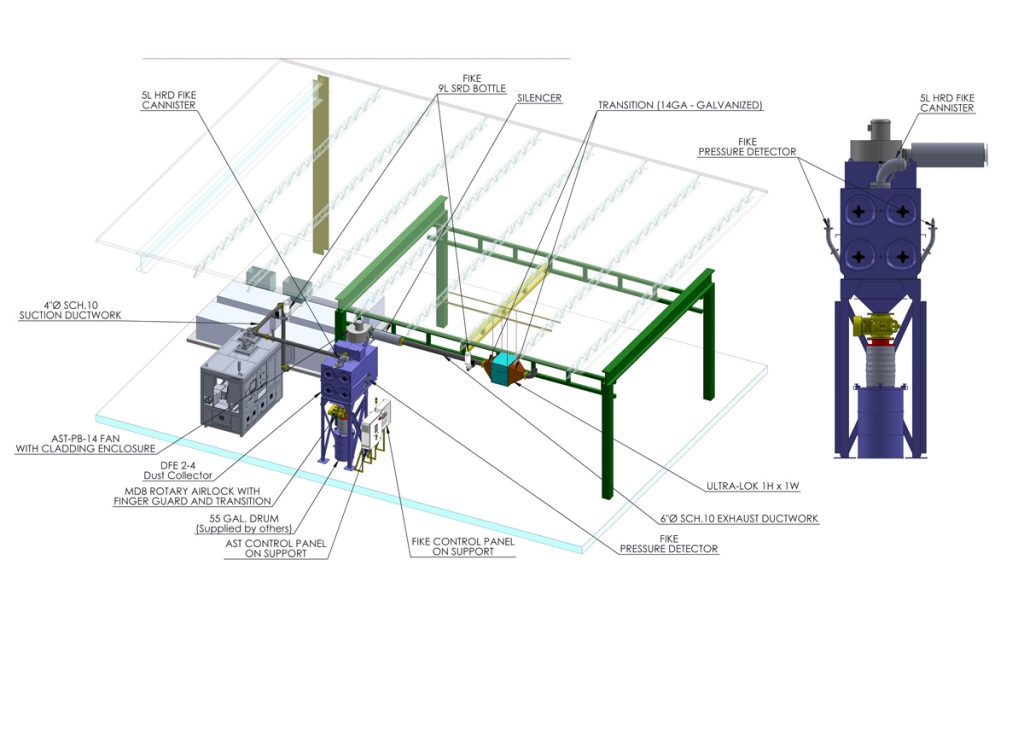

These metal industrial dust collection fittings are simply the best you can findperiod. The Quick-Fit system features simple to use clamps with nitrile seals welded heavy gauge galvanized pipe. Small system mounted locally directly on the equipment where the dust emission can happen.

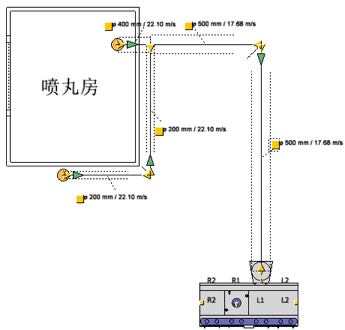

Users can access DuctQuote to design dustmistfume collection systems at a rate of 20 machine connections per hour. Draw a floor plan of your shop 2. Dust Collection System Design Calculations.

IndiaMART Computer and Mobile Softwares Apps Application Software Packages. Determine Diameter and CFM of Main Duct 5. Todays top 10 high paying Job roles.

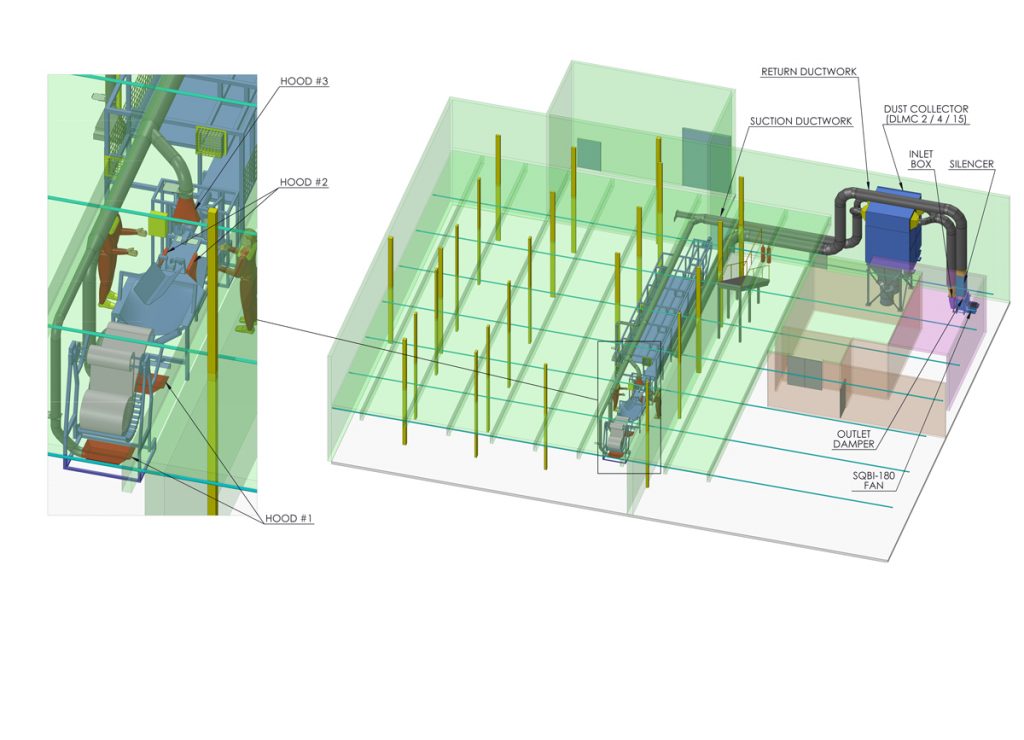

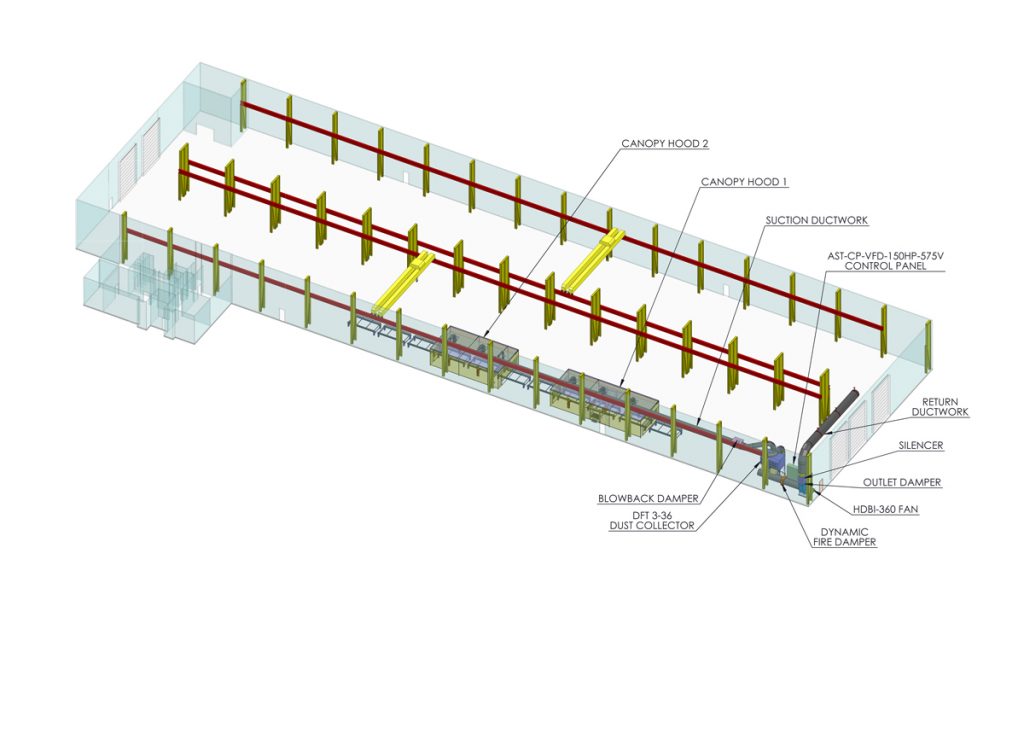

The centralized dust collection system collects the flying fluffs from four parallel travelling cleaner. In the balance by design method the duct size and layout is engineered to balance the airflow in the systems branches pickups and trunk based on static pressure loss through each section. In a separate article I will walk through the dust collection design at each tool in my shop to help you complete your dust collection system design.

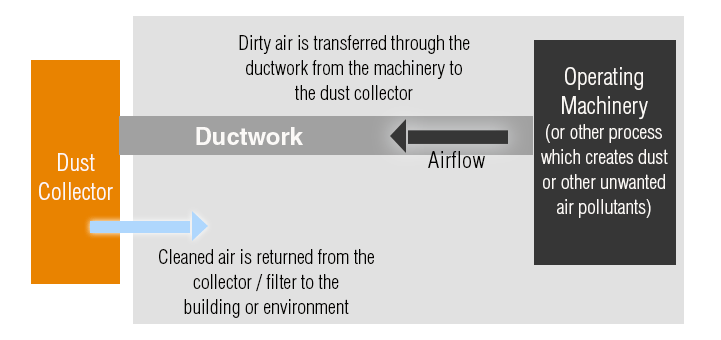

System Design Variables For a dust collection system to function ade-quately engineers must design and operate the system to maintain the 4 key design parameters of CFM FPM Vacuum Pressure and Air to Cloth Ratio or AC. Both types have in common to have a fan to suck air and carry dust away from the working area and a.

There is a large amount of misinformation about what the proper size pipe is to run.

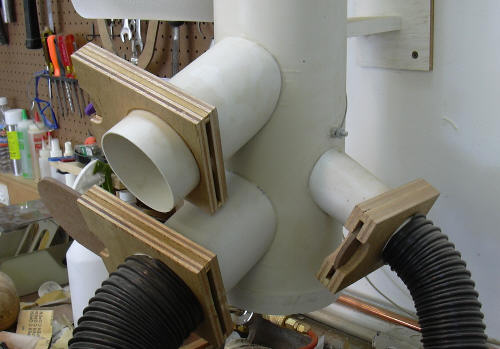

Nordfab dust collection ductwork includes fittings and pipes that range from 3 - 24 in diameter and feature double-rolled connecting edges that clamp into place to provide heavy-duty seals. When balancing the airflow and more importantly air velocity in a dust collection system there are two main approaches. Dust Collector Duct Design. Both types have in common to have a fan to suck air and carry dust away from the working area and a. AST Engineering experts will visit your plant and review your application in details. Leverage your professional network and get hired. The first phase is sizing your duct work for adequate volume and velocity of flow for the type of dust you will be creating. Certain machines should be located closer to your dust collectors. These metal industrial dust collection fittings are simply the best you can findperiod.

It will start with the picking a dust collector and go all the way to fully automated blast gates. There are two phases to designing your dust collection system. Small system mounted locally directly on the equipment where the dust emission can happen. In a separate article I will walk through the dust collection design at each tool in my shop to help you complete your dust collection system design. Local dust aspiration system. Nordfab dust collection ductwork includes fittings and pipes that range from 3 - 24 in diameter and feature double-rolled connecting edges that clamp into place to provide heavy-duty seals. Generates custom quotes using your logo and contact info.

.jpg)

Post a Comment for "Dust Collection System Design Software"